With a fully enclosed structure, the YG rotary pressure filter combines washing, extraction, steaming and drying together, and it uses a rotary drum to automatically and continuously retain solid particles in solid-liquid mixtures, thus realizing effective solid liquid separation.

Featuring continuous discharging, high handling capacity, good dewatering effect, small footprint and high degree of automation, this continuous filter dryer is often used to rapidly separate solids from various suspensions, and it is compliant with GMP and FDA requirements.

Technical Data of Rotary Pressure Filter| Model | Filter area(m2) | Drum diameter (mm) | Machine size (mm) | Weight (kg) |

| 0.12 | 500 | 1000×900×1600 | 900 | |

| 0.54 | 750 | 2000×1900×1800 | 3300 | |

| |

1.08 | 750 | 2300×1900×1800 | 3700 |

| 1.44 | 1000 | 2500×2100×2200 | 5900 | |

| |

2.16 | 1000 | 2700×2300×2200 | 7300 |

| 2.88 | 1000 | 3300×2400×2500 | 8500 | |

| 3.20 | 1500 | 3100×2900×3200 | 11500 | |

| |

4.32 | 1500 | 3700×3000×3200 | 14000 |

| 5.76 | 1500 | 4000×3000×3200 | 17500 | |

| |

7.68 | 2000 | 4300×3400×4000 | 23500 |

Technical Characteristics

1. Washing Cycle

Filter cakes with special structure and density can be washed in one or several stages, and our machine’s unique structure minimizes the use of wash liquid. On the other hand, used wash liquid is discharged via a liquid outlet, and filter cakes are separated by the control head. If necessary, filter cakes will return to filtration step.

2. Cake Discharge

In a rotary pressure filter, filter cake usually drops spontaneously due to its own gravity. However, if it fails to drop as a result of adhesive force, it will be discharged by scraper or gas back flushing. In addition, washing pressure is designed to 25bar at the most, and this makes it possible to clean the filter cloth in the same direction as it filters the feed suspension.

3. Continuous Operation

Unlike traditional ones, our rotary drum filter is able to work continuously, and this makes it extremely suitable for harmful or poisonous solid-liquid mixture.

4. Perfect Sealing

Due to its perfect sealing, there is no need to worry about leakage even when dealing with filter pulps that contain methyl or alcohol methylbenzene.

5. High Efficiency

The rotary drum finishes filtration, washing, dewatering and discharging in one revolving cycle, thus greatly enhancing production efficiency.

6. Low Filter Cake Moisture

Aside from pressure filtration, our rotary filter also takes advantage of compressed air, superheated steam or hot gas to dry filter cakes.

Application Fields

Our rotary pressure filter is commonly used in food, coal, mining, chemical, petrochemical, pharmaceutical, water treatment and other industries

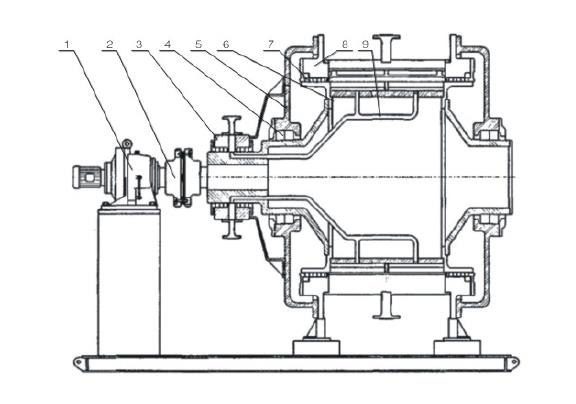

| 1. Speed Reducer 2. Coupler 3. Distributor |

4. Bearing 5. End Cover for Outer Rotary Drum 6. Inner Rotary Drum |

7. Packing Seal 8. Outer Rotary Drum 9. Pipe |