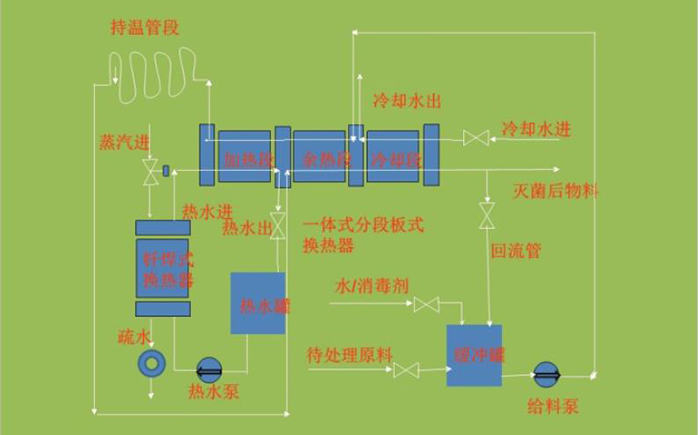

The continuous sterilization system has a quite self-explanatory name, indicating that it is designed for the continuous sterilization of culture medium during fermentation process. More specifically, when pre-heated culture medium is transported to the fermentation tank, our disinfection system will heat up, thermally isolate and then cool the culture medium, realizing continuous sterilization.

Main Characteristics

1. During work, high temperature sterilization lasts for less than 1 minute, and this not only helps to enhance production efficiency, but also saves a lot of steam and cooling water. However, if sterilization is performed inside the fermentation tank, several hours will be necessary.

2. As a result of the high temperature and short sterilization time, microorganisms are killed thoroughly without doing damage to growth medium.

3. Our continuous sterilization system requires short preparation time, allowing it to deal with more culture media.

4. Either a spiral plate heat exchanger or a flat plate heat exchanger is used, and its single channel design is very effective in reducing scaling and corrosion, even when there are heavy granules in the material.

5. Our sterilization equipment has a high heat recovery rate which could reach up to 60%-80%, thus saving a lot of steam and cooling water.

6. This continuous sterilizer is compliant with GMP requirements, and it allows easy operation as well as automatic control.

| Model | |

|

|

|

| Production capacity (t/h) | 1 | 5 | 10 | 20 |

| Material inlet temperature (°C) | 15 | 15 | 15 | 15 |

| Material outlet temperature (°C) | 15 | 15 | 15 | 15 |

| Sterilization temperature (°C) | 135 | 135 | 135 | 135 |

| Cooling water pressure (MPa) | 0.4 | 0.4 | 0.4 | 0.4 |

| Steam pressure (MPa) | 0.5 | 0.5 | 0.5 | 0.5 |

| Compressed air pressure (MPa) | 0.4 | 0.4 | 0.4 | 0.4 |

| Connection pipe size (mm) | Φ38 | Φ38 | Φ51 | Φ63 |

| Machine size (mm) | 2000×1500×2000 | 2500×1500×2000 | 2500×2000×2500 | 3000×2500×3000 |