Conforming to GMP and FDA directives, the filtering, washing and drying equipment is a 3-in-1 device that is able to finish material mixing, reaction, filtration, washing, dewatering and drying operations one by one in its enclosed chamber, and it exhibits many features, like simple structure, simplified work flow, high production efficiency, no cross contamination, convenient material change, low initial investment, high degree of automation, etc. So, this filtration system is widely used in food, dyeing, chemical and pharmaceutical industries.

Technical Data of Aseptic/Foldable Filtering Washing and Drying Equipment| Model | UNFCD 700 |

UNFCD 800 |

UNFCD 900 |

UNFCD 1200 |

UNFCD 1600 |

UNFCD 2000 |

UNFCD 2200 |

UNFCD 2600 |

| Nominal filter area (m2) | 0.38 | 0.5 | 0.63 | 1.1 | 2 | 3.1 | 3.8 | 5.3 |

| Inner diameter (mm) | 700 | 800 | 900 | 1200 | 1600 | 2000 | 2200 | 2600 |

| Nominal volume (m3) | 025 | 0.35 | 0.5 | 1 | 2 | 3 | 4 | 5 |

| Bucket height (mm) | 690 | 800 | 800 | 1000 | 1000 | 1000 | 1000 | 1000 |

| Filter cake thickness (mm) | 200 | 200 | 300 | 400 | 400 | 400 | 400 | 400 |

| Standard Model | UNFCD 900 |

UNFCD 1200 |

UNFCD 1600 |

UNFCD 2000 |

UNFCD 2200 |

UNFCD 2600 |

| Nominal filter area (m2) | 0.63 | 1.1 | 2 | 3.1 | 3.8 | 5.3 |

| Inner diameter (mm) | 900 | 1200 | 1600 | 2000 | 2200 | 2600 |

| Nominal volume (m3) | 0.5 | 1 | 2 | 3 | 4 | 5 |

| Bucket height (mm) | 800 | 1000 | 1000 | 1000 | 1000 | 1000 |

| Filter cake thickness (mm) | 300 | 400 | 400 | 400 | 400 | 400 |

Note:

1. All the above technical data are subjected to change without prior notice.

2. The industrial/fixed type can be customized, and its max. volume could reach up to 20m3.

Main Characteristics of Filtering, Washing and Drying Equipment

1. Hermetically Sealed Structure

Our multifunctional filtration equipment is hermetically sealed, so it totally avoids air pollution which is otherwise caused by the solvent, and also protects operators since there is no possibility for them to come into contact with toxic matters.

2. Thorough Recycling

Feed suspension and corresponding solvent are recycled almost completely so as to reduce material/solvent waste and therefore bring more economic benefit. This is particularly important when dealing with expensive materials and solvents.

3. Simultaneous Drying

This filtering equipment is fitted with heater on its wall, thus enabling it to finish filtration, washing and drying in one chamber.

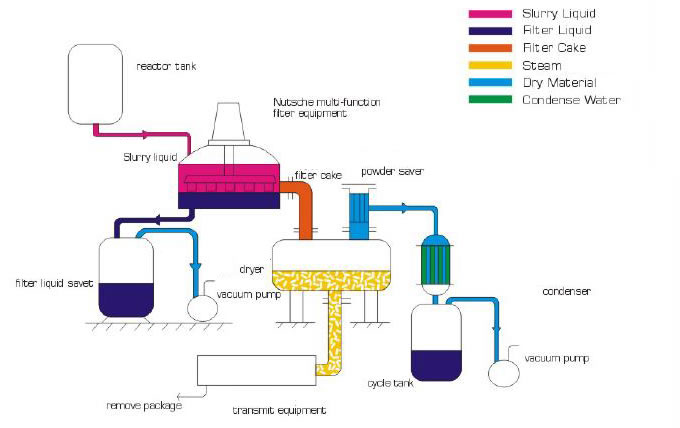

4. Good Adaptability for Production Line

For the filtering, washing and drying equipment, it is not necessary for operators to transport or store wet cakes because it can be integrated into a production line easily. For example, if a dryer is set beneath this equipment, wet cakes can be discharged into this dryer to get dried. Then, dried cakes are delivered to weighing, packaging or other working sites.

5. Labor Saving Operation

After a simple training course, even non-technical staff could finish the entire production process without monitoring our machine all the time.

6. Complete Cleaning

Due to the automatic liquid spraying function, filter cakes can be cleaned thoroughly, and less wash liquid is required when compared with similar equipment, thus cutting down the cost for sewage treatment.

7. Hygienic Production

A dust collector is employed to collect dust generated during production, enabling this filtering, washing and drying equipment to provide hygienic production process.