Main Characteristics

1. The L(P)GZ(MDL)/SGZ(MDL) top driven bottom discharge centrifuge uses a coupler to connect motor and shaft directly, and this design helps to avoid particulate matter emission which is often seen for conventional transmission.

2. The housing and base plate are welded together, and a frequency converter is used to regulate revolving speed, thus ensuring stable start and protecting the motor from overload.

3. Our vertical centrifuge takes advantage of a PLC controller to realize automatic operation, and it is equipped with an auxiliary pneumatic scraper to remove residual heel for better separation result.

4. For the L(P)GZ(MDL) top driven bottom discharge centrifuge, it has a liquid shock absorber, and this device guarantees stable running and convenient operation.

| Model | |

|

|

|

|

|

|

| Drum diameter (mm) | 1250 | 15C0 | 1600 | 1250 | 1500 | 1600 | 1600 |

| Drum height (mm) | 630/800 | 700 | 920 | 630/800 | 800 | 920 | 1000 |

| Drum capacity (L) | 350/450 | 500 | 970 | 350/450 | 580 | 970 | 1000 |

| Max. loading capacity (kg) | 460/580 | 650 | 1300 | 460/580 | 720 | 1200 | 1300 |

| Drum speed (r/min) | 970 | 850 | 850 | 970 | 850 | 850 | 850 |

| Max. separating factor | 657 | 605 | 646 | 657 | 605 | 646 | 646 |

| Motor power (kW) | 22/30 | 37 | 45 | 22/30 | 37 | 45 | 45 |

| Machine size with shock absorber (mm) | 2003×1780×2600 2003×1780×2780 |

2700×2500×2870 | 2700×2500×3000 | 2000×2000×2266 2000×2000×2396 |

2500×2500×2650 | 2500×2500×2800 | 2500×2500×3000 |

| Weight (kg) | 5000/5200 | 9200 | 11500 | 5800/6000 | 12200 | 13300 | 13700 |

Main Material

1. Cover and chassis: Q235 lined with stainless steel

2. Bearing seat and drum bottom: Cast steel lined with stainless steel

3. Housing, pipe and drum (except its bottom): Stainless steel

Standard Structure

1. L(P)GZ(MDL) adopts platform structure, and SGZ(MDL) is supported by three point suspension.

2. For this filtering centrifuge, its bucket and base plate are welded together, while its bearing seat and cover are welded and then connected to the housing by flanges and bolts.

3. On the cover, there is feed pipe, wash pipe, sight glass, observation light, fill level controller, manhole and other devices.

Standard Configuration

1. Frequency converter and PLC controller

2. Dynamic braking system

3. Fill level controller (contact type)

4. Vertical explosion proof motor

5. Anti-explosion operation box

6. Hydraulic scraper unit

Material Option

Based on customer requirements in corrosion resistance, different materials can be adopted to fabricate our vertical scraper centrifuge, like 316, 316L, 321, 304, TA2, Hastelloy, lined rubber, etc. In addition, Halar coating is also available.

Parameter Option

To better meet every individual needs, our top driven bottom discharge centrifuge could be supplied with different drum volume (maximum loading capacity).

Configuration Option

1. Variable frequency explosion proof motor or common motor (fixed torque)

2. Pneumatic scarper

3. Regenerative braking system

4. Common or explosion proof touch screen

5. Vibration protection, inert gas (nitrogen) protection

6. Revolving speed indication

7. Oxygen content detection or nitrogen pressure control

8. Liquid seal for original suspension

9. CIP system and auxiliary pneumatic scraper

10. Non-contact fill level control

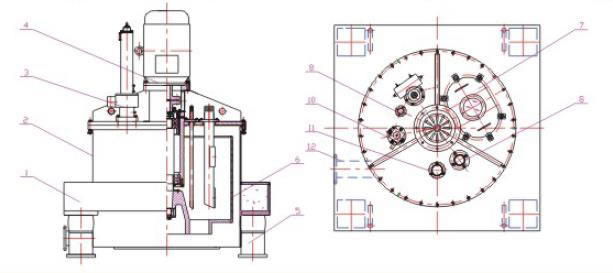

| 1. Base Plate 2. Housing 3. Oil Cylinder Group 4. Motor |

5. Shock Absorber 6. Revolving Drum 7. Manhole 8. Feed Pipe |

9. Wash Pipe 10. Fill Level Controller 11. Explosive-proof Light 12. Water Outlet |