Main Characteristics

1. The SS/L(P)S centrifuge for filtration and dewatering, as indicated by its name, is not only suitable for the separation of suspension, but also fits for the dewatering of fiber products and dyed textiles.

2. With a simple yet scientifically designed structure, this vertical top discharge centrifuge allows easy operation and maintenance, and its structural components are smooth and well polished.

| Model | |

|

|

|

|

|

|

| Drum diameter (mm) | 200 | 300 | 450 | 600 | 800 | 1000 | 1200 |

| Drum capacity (L) | 3 | 10 | 20 | 45 | 90 | 140 | 250 |

| Drum height (mm) | 140 | 210 | 300 | 350 | 400 | 420 | 440 |

| Max. loading capacity (kg) | 3.5 | 12 | 30 | 68 | 135 | 200 | 300 |

| Drum speed (r/min) | 3000 | 2800 | 2000 | 1600 | 1200/1500 | 1080/1200 | 950 |

| Max. separating factor | 1007 | 1315 | 1007 | 860 | 645/1007 | 652/805 | 605 |

| Motor power (kW) | 0.55/0.75 | 1.5 | 3 | 3 | 5.5/7.5 | 11 | 15 |

| Weight (kg) | 45 | 160 | 500 | 800 | 1320/1400 | 2000/2200 | 2600 |

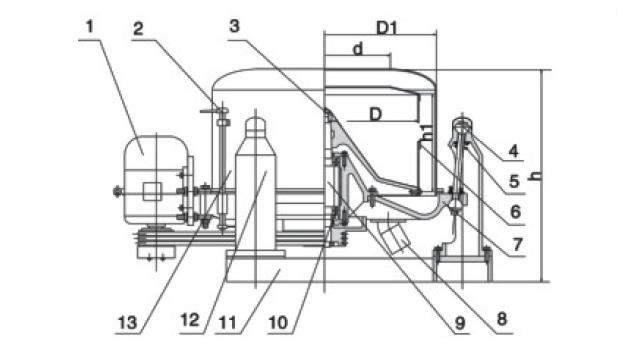

| 1. Motor 2. Braking System 3. Oil Inlet 4. Boom 5. Boom Spring |

6. Drum 7. Chassis 8. Liquid Outlet 9. Main Axle |

10. Bearing 11. Triangle Ring 12. Pedestal 13. Housing |

| Model | |

|

|

|

|

|

| Drum diameter (mm) | 300 | 450 | 600 | 800 | 1000 | 1200 |

| Drum capacity (L) | 10 | 20 | 45 | 90 | 140 | 250 |

| Drum height (mm) | 210 | 300 | 350 | 400 | 420 | 440 |

| Max. loading capacity (kg) | 12 | 30 | 68 | 135 | 200 | 300 |

| Drum speed (r/min) | 2800 | 2000 | 1600 | 1200/1500 | 1080/1200 | 950 |

| Max. separating factor | 1315 | 1007 | 860 | 645/1007 | 640/805 | 605 |

| Motor power (kW) | 1.5 | 3 | 3 | 5.5/7.5 | 11 | 15 |

| Weight (kg) | 220 | 550 | 950 | 1400/1500 | 2400/2500 | 3200 |

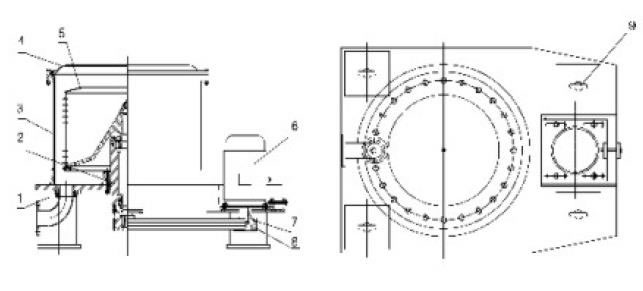

| 1. Shock Absorber 2. Bearing Seat 3. Housing |

4. Cover 5. Drum 6. Motor |

7. Belt Pulley 8. V Belt 9. Lifting Ring |

Material Option

If requested, our dewatering centrifuge can be manufactured from lined rubber, lined plastics, Hastelloy, titanium alloy or other materials. In particular, F46, Halar and other coatings are also available.

Structural Option

1.Sealed cover with feed pipe, wash pipe, viewing light, viewing hole, cover opening device and others

2. Direct connected motor and relevant frequency converter (with common shock absorber)

3. Stainless steel covered pedestal and triangle ring (chassis)

4. Other requirements