As a bottom discharge filter centrifuge, the SX three point suspension centrifuge requires little user interaction but is able to deliver satisfying performance. Mainly intended for the separation of small to medium sized solid particles (0.01mm) suspended in liquids, it is also applicable for crystallized suspension and fiber materials.

Main Characteristics of Three Point Suspension Centrifuge

Aside from the merits of traditional three point top discharge centrifuge, this three point suspended centrifuge also exhibits many other outstanding properties.

1. Due to the implementation of bottom discharge, labor intensity is reduced to a large extent, and working efficiency is significantly improved at the same time.

2. Since the discharge process is conducted manually instead of by a scraper, there is no need to install a scraper. From this point of view, this separation equipment is a great choice for conditions where solids are not allowed to get damaged.

3. All the components that will come into contact with liquid are manufactured from stainless steel, and customers could specify other materials according to their needs.

Owing to the abovementioned properties, the three point suspension centrifuge is commonly used in chemical, food, pharmaceutical and other industries.

Technical Data of Three Point Suspension Centrifuge| Model | |

|

|

| Drum diameter (mm) | 800 | 1000 | 1250 |

| Drum speed (r/min) | 1500 | 1200 | 1000 |

| Max. separating factor | 1007 | 805 | 698 |

| Drum capacity (L) | 90 | 140 | 250 |

| Loading capacity (kg) | 135 | 200 | 300 |

| Motor model | Y132M-4 | Y160M-4 | Y180M-4 |

| Motor power (kW) | 7.5 | 11 | 11 |

| Transmission type | V-belt | - | 18.5 |

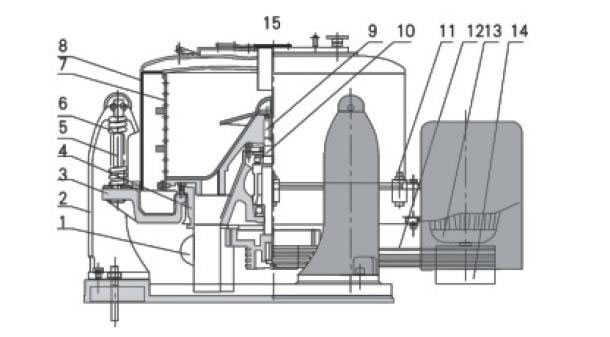

| 1. Drain Hole 2. Pedestal 3. Chassis 4. Bearing Seat 5. Boom |

6. Spring 7. Drum 8. Housing 9. Shaft 10. Bearing |

11. Bolt 12. V-belt 13. Motor 14. Centrifugal Clutch |